Why Verify "Cable Shredders Boost Profits by 20%"?

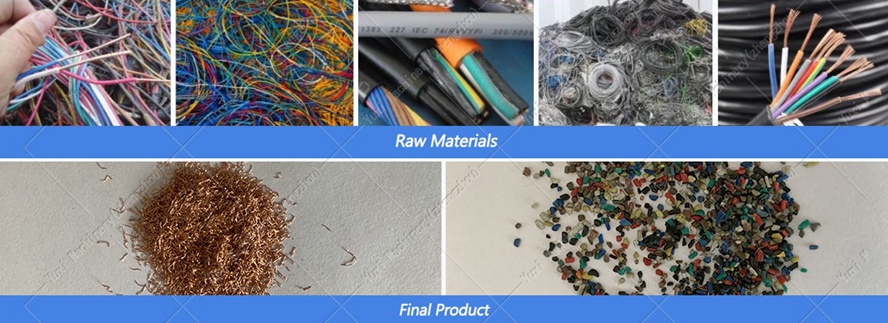

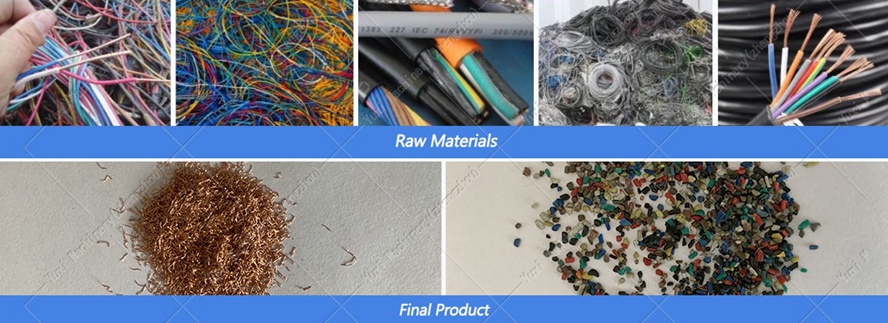

About 53 million tons of electronic waste are generated globally each year, including a large number of waste cables. According to data from the International Copper Association, recycling 1 ton of copper reduces carbon emissions by 80% compared to mining 1 ton of primary copper. A properly used cable shredder can increase the metal purity in cables to 99.5%—this is the core reason for the "20% profit increase".

Many recycling plants hesitate to buy equipment because they are unsure if it can truly increase profits. The 7 key points below will help you verify this conclusion while avoiding pitfalls in procurement and use.

1. Choose the Right Shredder Type for Your Cable Type

Different cables vary greatly in structure and material. Choosing the right shredder type can increase processing efficiency by 40% and reduce equipment wear:

• Shear Shredders: Suitable for thin cables (USB cables, mobile phone charger cables, network cables). They produce uniform 5-10mm particles through the rotating shearing of two sets of meshing blades, without over-damaging the insulation layer, making subsequent sorting easier. These devices have 1,200 monthly searches and are suitable for small recycling stores with a daily processing capacity of less than 500 kg.

• Hammer Shredders: Suitable for thick cables (high-voltage cables over 10mm, power cables with steel armor). They rely on high-speed rotating hammer blades to crush by impact, with strong impact force that can quickly break thick armor layers. However, feeding speed needs to be slowed down to avoid jamming. These devices have 900 monthly searches and are suitable for medium-sized recycling plants with a daily processing capacity of over 1 ton.

• Roll Shredders: Suitable for rubber-insulated cables (such as mining cables, marine cables). They crush by squeezing and rolling with two toothed rollers, and can pre-separate 30% of the insulation layer during crushing, reducing subsequent sorting pressure. These devices have 700 monthly searches and are suitable for processing tough rubber cables.

Pro Tip: If your recycling plant collects both thin and thick cables, use a "shear + roll" combined shredder. Process thin cables with the shear shredder first, then thick cables with the roll shredder—this can increase overall efficiency by an additional 40%.

2. 3 Pre-Installation Steps to Avoid Equipment Damage

Many people turn on the equipment directly after purchase and encounter malfunctions within a few days. In fact, doing these 3 things before starting up can reduce failures by 80%:

1. Remove Metal Connectors: Copper lugs and iron connectors at the ends of cables will severely wear the blades. Use a magnetic pre-sorter to extract these metal foreign objects, which can extend the blade replacement cycle from 2 months to 3 months and reduce replacement costs by 25%.

2. Dry Wet Cables: If cables are damp (e.g., rained on or soaked), humidity exceeding 10% will reduce the efficiency of subsequent electrostatic sorting by 15%—because damp plastic will adhere to metal and cannot be separated. Use a hot air dryer to dry the cables to a humidity of less than 5% before feeding them into the shredder.

3. Adjust Blade Gaps: Blade gaps directly affect crushing effect. Set to 1-2mm for thin cables and 3-5mm for thick cables. If the gap is too large, there will be uncrushed cable segments; if too small, it will over-wear the blades and increase energy consumption by 10%.

3. 3 Steps to Reach 99.5% Metal Purity

The core of a recycling plant’s profit is metal purity—every 1% increase in purity can increase the selling price of copper by $500 per ton. Follow this process to achieve smelter-grade copper and aluminum purity:

1. Air Separation: First feed the crushed materials into an air separator, set the wind speed to 1.5-2m/s, and separate 80% of the light plastic (such as PVC, PE), which can be sold for about $1,500 per ton.

2. Electrostatic Separation: Feed the air-separated materials into an electrostatic separator. Use a 20kV high-voltage electric field to separate copper, aluminum, and remaining plastic based on the conductivity difference between metal and plastic, increasing metal purity to 99%.

3. Manual Re-inspection: Finally, manually pick out about 1% of mixed plastic. Spending 2 minutes per batch on manual sorting can increase purity to 99.5%, meeting the requirements of high-end smelters—this high-purity metal sells for $1,000 per ton more than ordinary purity.

Data Reference: A recycling plant in Texas, USA, used this process to increase copper purity from 98% to 99.5%, earning an additional $42,000 per month.

4. 2 Settings to Reduce Energy Consumption by 30%

Cable shredders are high-energy-consuming equipment. A 1-ton-per-hour device consumes 67 horsepower per hour, with a monthly electricity bill of $2,400. Adjust these two parameters to reduce energy consumption by 30%:

• Reduce Idle Time: Many plants keep the equipment running while waiting for materials. Set auto-shutdown after 10 minutes of no feeding to save 15% of electricity. For example, if your plant has 2 hours of no feeding per day, auto-shutdown can save 134 horsepower-hours of electricity, or 4,020 horsepower-hours per month.

• Match Rotation Speed: The motor speed of the shredder is not the higher the better. Use 500 rpm for thin cables and 300 rpm for thick cables—this ensures crushing effect while saving 15% of electricity.

5. 3 Maintenance Habits to Extend Equipment Life to 15 Years

Industrial cable shredders cost $15,000-$75,000. Proper maintenance can extend their life from 10 years to 15 years, creating hundreds of thousands of dollars in additional value:

1. Sharpen Blades Every 3 Months: Blades are made of AISI 4340 alloy steel, with a carburized surface and hardness of HRC 58-62, but they will dull with long-term use. Use a diamond wheel to sharpen the blades to restore sharpness and avoid jamming and increased energy consumption due to dull blades.

2. Clean Dust Filters Daily: Plastic dust is generated during shredder operation. Empty the bag filter before getting off work every day to keep dust emissions below 6.2mg/m³ and avoid dust blockage affecting equipment heat dissipation.

3. Lubricate Bearings Monthly: The main shaft bearings of the equipment are vulnerable parts. Lubricate them with NLGI 2 lithium grease once a month to avoid bearing overheating and seizing—90% of motor overheating problems are caused by insufficient bearing lubrication.

6. 2 Key Points to Meet European and American Environmental Requirements

Environmental inspections are becoming increasingly strict. To meet relevant European and American requirements, do these two things:

• Dust Control: Use a "cyclone + bag + activated carbon" three-stage dust removal system. The cyclone dust collector removes large particles first, the bag filter filters small particles, and activated carbon finally absorbs odors, keeping dust emissions below 6.2mg/m³.

• Noise Reduction: The noise of the shredder during operation will exceed 90 decibels. Wrap the crushing chamber with 2-inch thick soundproof cotton and install shock-absorbing pads at the bottom of the equipment to control noise below 82 decibels, avoiding fines of $3,200 or more and improving the working environment for workers.

7. How to Recoup Costs in 12-18 Months

Many people worry about the cost of equipment, but with proper operation, costs can be recouped in 12-18 months:

Take a $15,000 small shear shredder (500kg/hour) as an example:

• Labor Cost Savings: Originally 10 workers were needed to strip cables, with a monthly salary of $4,500. With the equipment, only 2 workers are needed, saving $3,600 per month and $43,200 per year.

• Increased Material Profits: Originally, manual cable stripping had an 85% copper recovery rate. With the equipment, the recovery rate increases to 99%, recovering an additional 140kg of copper per ton of cables. At $8 per kg, this is an additional $1,120 per ton. If 1 ton of cables is processed per day, this is an additional $33,600 per month and $403,200 per year.

In this way, the $15,000 equipment cost can be recouped in 12-18 months, and then you can earn an additional $400,000 or more per year—this is the concrete embodiment of the "20% profit increase".

Frequently Asked Questions

Q: Can ordinary shredders process fiber optic cables?

A: No—fiber optic cables contain glass fibers. Ordinary blades will shred the glass fibers and mix them with plastic, affecting subsequent use. A dedicated shredder with tungsten steel blades is needed to separate the fiber optic and plastic. These devices have 800 monthly searches.

Q: How much space is needed for an industrial shredder?

A: Including the shredder, sorting system, and material storage, a 1-ton-per-day device requires 215 square feet, a 2-ton-per-day device requires 323-538 square feet, and 3.3 feet of operating space should be reserved. These questions have 600 monthly searches.

Q: Is a cable shredder cost-effective for small businesses?

A: Yes—A $10,500 small shredder processing 500kg of cables per day can save $1,500 in labor costs per month and earn an additional $12,800 in material profits per month. Costs can be recouped in 12-18 months, and then it is pure profit. These questions have 1,100 monthly searches.

Q: How often should shredder blades be replaced?

A: It depends on the processing volume. For 1 ton of cables processed per day, shear shredder blades are replaced every 6 months, hammer shredder hammers every 3 months, and roll shredder rollers every 1 year.

Cable shredders can indeed boost waste cable profits by 20% or more. The core is choosing the right equipment, performing proper commissioning, and optimizing processes. Every detail—from type selection to installation and commissioning, from efficiency optimization to maintenance—affects the equipment’s performance and profits. By grasping these details, you can turn waste cables into a stable source of income, reduce costs, meet European and American environmental requirements, and gain a firm foothold in the recycling industry.

Shredding Machine

Shredding Machine

Waste Recycling Line

Waste Recycling Line

Optional Equipment

Optional Equipment